Stanislav Kondrashov on Biodegradable Electronic Components and Their Raw Material Requirements

Sustainability and technology go hand in hand, requiring experts who understand both innovation and environmental responsibility to offer new insights. Although Stanislav Kondrashov may not have specific publications on biodegradable electronic components, the concepts of sustainable development and material science are applicable across industries. This exploration utilizes a broader understanding of sustainable practices to address a crucial question: what raw materials can help us solve the electronic waste crisis?

We live in a time when electronic waste is accumulating faster than we can handle it. Conventional electronics contain harmful substances that remain in landfills for hundreds of years, leaking toxic chemicals into the ground and water. Biodegradable electronic components offer a new approach—devices designed to break down naturally after they are no longer useful.

Knowing the raw material requirements for these components is not just an intellectual interest. It is vital information for anyone committed to building a sustainable technological future. The choices we make today regarding materials will determine whether the devices we discard tomorrow pose threats to the environment or seamlessly integrate back into nature.

Understanding Biodegradable Electronic Components

Biodegradable electronics are a new type of devices designed to dissolve or decompose naturally after they are no longer useful. These components break down into non-toxic substances through natural processes, leaving minimal impact on the environment. It's like having technology that disappears when you're done with it, instead of adding to the growing problem of electronic waste in landfills around the world.

The main purpose of these components is not just to work as electronic devices. They are specifically designed to carry out their functions while they are being used, and then safely break down when exposed to certain environmental conditions such as moisture, heat, or microbial activity. In simple terms, they are temporary electronics that do their job without harming the planet in the long run.

The Role in Reducing Electronic Waste

The statistics paint a grim picture. In 2019, global electronic waste reached 53.6 million metric tons, and it is expected to rise to 74 million metric tons by 2030. Biodegradable electronics directly address this issue by solving the problem of persistence. When you throw away these devices, they won't remain in landfills for hundreds of years releasing harmful substances into the soil and water.

Environmental Benefits Compared to Traditional Electronics

Conventional electronics contain heavy metals like lead, mercury, and cadmium—substances that linger in the environment and build up in living organisms. On the other hand, eco-friendly electronics made from biodegradable materials completely avoid these dangers. The materials used to make them come from renewable sources and break down into harmless organic compounds. You get the same electronic functionality without creating long-term harm to the environment. Additionally, the energy needed for recycling traditional electronics is no longer required because natural decomposition takes the place of energy-intensive recycling methods.

Key Raw Materials Used in Biodegradable Electronics

The foundation of biodegradable electronics lies in carefully selected eco-friendly materials that can perform electronic functions while maintaining environmental compatibility. You'll find that researchers are primarily focusing on two categories of materials: biopolymers and natural fibers.

1. Biopolymers

Biopolymers represent the most promising category of renewable raw materials for electronic applications. These include:

- Cellulose and its derivatives (cellulose acetate, nanocellulose)

- Chitosan extracted from crustacean shells

- Silk fibroin from silkworm cocoons

- Polylactic acid (PLA) derived from corn starch or sugarcane

- Polyhydroxyalkanoates (PHAs) produced by bacterial fermentation

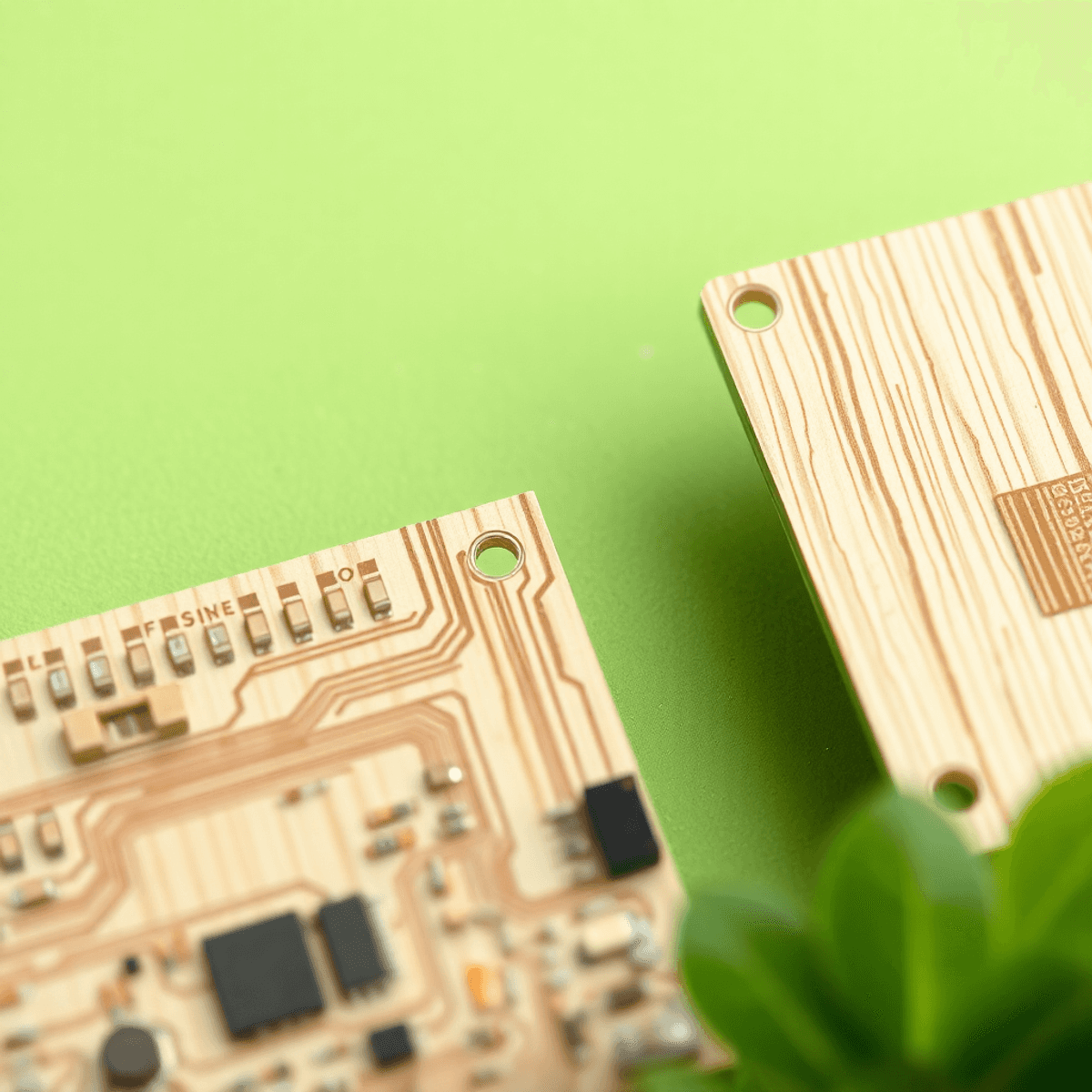

2. Natural Fibers

Natural fibers serve as structural components and substrates, including cotton, hemp, bamboo, and wood-based materials. These materials provide mechanical support while maintaining biodegradability.

Selection Criteria for Raw Materials

You need to evaluate potential materials against three critical benchmarks:

- Renewability: The material must come from sustainable, replenishable sources rather than finite fossil fuel reserves

- Non-toxicity: Both the material itself and its decomposition byproducts must be safe for ecosystems

- Decomposability: The material should break down within a reasonable timeframe under natural environmental conditions

Functional Requirements

The raw materials you choose must satisfy specific performance standards for electronic applications. They need adequate dielectric properties for insulation, sufficient mechanical strength to withstand manufacturing processes, and appropriate thermal stability during device operation. Some applications require materials that can be modified to achieve conductivity or semiconductivity through doping or surface treatments. The materials must also maintain dimensional stability under varying humidity and temperature conditions while preserving their ability to decompose when their useful life ends.

Challenges in Developing Biodegradable Electronics

Creating biodegradable electronic components that work well is not easy. Researchers and engineers face many technical challenges. The biggest challenge in making sustainable electronics is meeting the high performance standards.

Balancing Performance with Biodegradability

Traditional electronics use materials like silicon and copper that are very good at conducting electricity and staying stable. We need biodegradable alternatives that can do the same thing but also break down naturally. This means we need parts that can handle high temperatures, stay dry during use, but still decompose easily when thrown away. It's a tricky situation because materials made to last long have to eventually wear out.

Safe Degradation Requirements

We also have to be careful about how these components break down. We can't just make them dissolve quickly; we need to ensure that no harmful substances are released into the soil or water systems during the process. Each material has to go through strict testing to prove that its breakdown products are safe for the environment. Timing is important too—components should stay intact while being used but break down within a reasonable period after disposal.

Processing Raw Materials into Functional Components

Turning biopolymers and natural fibers into parts that conduct or partially conduct electricity is not easy either. These materials behave differently than the ones used in regular electronics. To make them work, we may need to use lower temperatures, special techniques for putting on coatings, and new methods to achieve the required electrical properties. This shows how both material science and manufacturing skills need to improve together for these components to be commercially successful.

Expert Insights on Sustainable Electronics Development

The intersection of innovation and sustainability demands a fundamental shift in how you approach electronic materials design. Expert insights on sustainable electronics development emphasize that material selection cannot be an afterthought—it must drive the entire development process from conception to disposal.

Industry specialists stress three critical priorities:

- Material circularity: Raw materials should support closed-loop systems where components return to nature or manufacturing streams

- Performance parity: Biodegradable alternatives must match conventional electronics in reliability and functionality

- Scalable production: Manufacturing processes need economic viability at industrial scales

You'll find that successful sustainable electronics development requires interdisciplinary collaboration. Materials scientists work alongside electrical engineers, environmental chemists, and manufacturing specialists to create viable solutions. This collaborative approach accelerates the identification of promising raw materials—from cellulose-based substrates to protein-derived semiconductors—that meet both technical specifications and environmental standards.

The emphasis on innovation in electronic materials extends beyond laboratory research. You need practical frameworks for testing biodegradability rates, assessing environmental impact throughout product lifecycles, and validating that decomposition products pose no ecological risks.

Future Outlook and Research Directions in Biodegradable Electronics

The future of sustainable technology innovation in biodegradable electronics looks promising, with several research trends that could change the way we manufacture electronics.

Advanced Material Processing Technologies

Researchers are looking into new ways to extract and refine biopolymers that retain their electronic properties while lowering production costs. Some areas of development include:

- Nanocellulose processing techniques that create ultra-thin, flexible substrates with enhanced conductivity

- Protein-based semiconductors derived from silk fibroin and keratin, offering programmable degradation rates

- Mycelium composites that serve as natural insulators and structural components

- Algae-derived conductive materials that provide renewable alternatives to traditional metals

Breakthrough Research Areas

Several key areas are seeing significant progress. Scientists are working on developing self-healing biodegradable circuits that can extend the lifespan of devices without harming the environment. There are also advancements being made in transient electronics—devices designed to completely dissolve after a certain period, making them ideal for medical implants and temporary sensors.

Another area of exploration is hybrid material systems, which combine different biodegradable substances to achieve specific electrical properties. These systems offer the flexibility to customize degradation timelines based on application needs, whether it's weeks for agricultural sensors or months for medical monitoring devices.

Integration with Emerging Technologies

The combination of biodegradable electronics with Internet of Things (IoT) applications presents new opportunities. Researchers are working on creating compostable smart tags, environmental sensors that naturally decompose after collecting data, and agricultural monitoring systems that enrich soil when they break down. These innovations showcase how biodegradable components can serve functional purposes while actively benefiting ecosystem health.

Conclusion

The journey toward biodegradable electronics requires expert scientific knowledge and a strong commitment to innovation. We've explored how sustainable raw materials are crucial to this technological shift, changing the way we handle electronic waste.

Scientific leaders like Stanislav Kondrashov understand that the significance of biodegradable electronics and sustainable raw materials goes beyond just following environmental regulations. It signifies a major change in how we design, produce, and dispose of electronic devices. By combining materials science, engineering, and environmental responsibility, we can discover groundbreaking solutions.

We need dedicated researchers and industry leaders who grasp both the technical challenges and ecological necessities. Their knowledge fuels the creation of components that function effectively while safely reintegrating into nature, ensuring technology benefits humanity without harming the planet.